Simplex Basket Strainer

Dynomech Simplex basket strainer, also called basket strainer filter or basket type strainer, is mainly used to mechanically remove unwanted solid from liquid and other commercial and industrial piping systems. Compare to other basket strainers suppliers, Our basket strainer has larger debris holding capacity and a longer lifetime while bringing you a less pressure drop.

You can send us your basket strainer flow rate, working pressure, and temp, pressure drop, or other basket type strainer specifications, our engineering sales will send you a basket strainer catalog and basic drawing in 8 working hours, also we can share you some similar case studies for your reference.

Dynomech Fabricated Basket Strainers are available in standard designs or can be custom designed and manufactured to fit your specific micron filter requirements. The standard basket strainer is designed and built in accordance with ASME Code Section VIII, Division 1. Available code designs include ANSI B 31.4, ANSI B 31.3, and ANSI B 31.8. Standard housing material is carbon steel, 304 stainless steel, or 316 stainless steel. Our Fabricated Basket Strainers can be supplied in ANSI flange ratings. We have the design capabilities and manufacturing facilities to handle your straining requirements up to 5 microns Fabricated Basket Strainers are available in pipe sizes from 2” to 24”.

Duplex Basket Strainer

Dynomech Duplex Strainer, as well as duplex type strainer or dual strainer, is a main basket strainer type manufactured. It is a perfect choice to provide continuous operation without any downtime during basket cleaning or change out. The major benefit of a duplex strainer is that there is no need to shut them off when they becom e clogged or need to be cleaned.

The strainer uses integral three way ball valves or Butterfly Valve with PTFE seals. This design provides drop tight shutoff eliminating costly and potentially dangerous leakage into the chamber not in use which can occur in some other duplex strainer designs. This also eliminates some problems which can occur in particular suction conditions where in other designs air ingress could occur. All parts of the valve mechanism are accessible after removing the basket chamber without taking the strainer out of the pipeline.

These duplex strainers and duplex filters protect pumps, engines, nozzles, valves, heat exchangers and other expensive pipeline equipment from harmful flow contamination by catching dirt and debris. Our duplex strainers and filters are suitable for process with high particle loading, and processes where it is not permissible to interrupt the process flow. Our build to order duplex strainers and filters are available in a number of different materials of construction including iron, steel, stainless steel, etc

Magnetic Filter/Strainers

Dynomech Magnetic Strainer is a perfect fit when it comes to protecting expensive pumping and heat exchange equipment from unwanted foreign material. The design features strainers are available in several configurations to catch large items. It also features a magnetized stem for removal of light, ferrous material from your product.Magnetic Filters are used for filtration of iron particles from products in liquid/slurry form. They are essentially used in chemical, food, pharma and oil industries. They are also frequently used in hydraulic circuits in cooling systems. The Filter Magnets are made up of either Ceramic or High-Intensity Rare Earth Magnets.

As the marketplace becomes increasingly competitive, more emphasis has been placed on reducing plant downtime and maintenance. In steam and condensate systems, damage to plant is frequently caused by pipeline debris such as scale, rust, jointing compound, weld metal and other solids, which may find their way into the pipeline system. Strainers are devices which arrest these solids in flowing liquids or gases, and protect equipment from their harmful effects, thus reducing downtime and maintenance. A strainer should be fitted upstream of every steam trap, flowmeter and control valve.

Self Cleaning Filter

Dynomech Self cleaning filter is specially designed for fluid filtration with continuous operation, saving the downtime and maintenance costs. The Self-Cleaning Filter is an efficient solution when it comes to industrial filtration. Used across a wide range of industries, its innovative design is suitable for many processing requirements, removing contamination from your liquid products. It is generally manufactured by quality 304/316L stainless steel material, and alloy can also be available for high-corrosion sea water applications The filter system consists of a cylindrical, cleanable filter which rotates against the stationery cleaning knife causing particles larger than the opening to be retained and eventually scraped off the element.

If you need an economical and reliable fluid filtration system, Dynomech self cleaning filter will be your optimal choice. With precision size design, strict quality control and perfect after-sale service.

Steam Jacketed Strainers/Filter

Dynomech Steam Jacketed strainers are used to keep materials hot that need to remain fluid such as chocolate, resins, polymers, and asphalt. This Steam Jacketed Strainer maintains its temperature by circulating steam or a heat transfer fluid through the strainer jacket. steam jacketed basket strainer / filter find importance in power plants, on ships & boilers where filtration of high viscosity. Steam jacketed strainers help keep the process fluid at the desired temperature Furnace oil is made more effective by heading with steam the hot low viscosity oil is easily filtered (i.e. Lower Pressure Drop is required). This a Steam Jacketed Strainer / Filter does the job of heating as well as filtering simultaneously there by reducing space & weight of equipment

Stainless Steel Strainer

Stainless steel strainers are available in various stainless steel classes, sizes, and other specifications. They may be developed for various industrial or commercial applications and can withstand a range of temperatures and pressures. They may also feature options such as steel butt welds, flanged ends, screwed end, and more.

Stainless steel strainers are an excellent choice for industrial or commercial applications that call for superior corrosion resistance. This is particularly important in the food and beverage industries as well as other sectors that require corrosion-free straining. Advantages of stainless steel strainers include:

Stainless steel (304 and 316) industrial strainer are made using an alloy of iron and chromium. The shiny appeal is attributed to the chromium composition in the alloy. Stainless steel material is also made from other elements such as nickel and titanium for different applications.

Pot Strainer

Dynomech Pot Type strainers in Flange End & Bolted cover design is suitable for domestic water services, chemical, Oil & HVAC Applications. Pot Type Casted body strainer remove particle from the process liquid and protecting system components such as flow meter, pumps, mechanical seals & spray nozzles.

The range of our Pot type strainers is smartly designed by the team of experts. Pot Type Strainers offered by us are the best quality in the market at industry leading prices. They are stringently tested on different parameters on industry standards to maintain quality. These Pot Type Strainers can be customized and manufactured in a wide range of required specification, temperature /pressure rating to meet training requirements Our Pot strainers are known for their convenient durability, high performance, and excellent efficiency as we are manufacturing them using superior quality material and the latest technology. Pot type strainers are designed as per larger filtration area and minimum pressure drop to obtain the desired flow rate in process industries. A variety of screen materials, as well as mesh size, can be offered for fine filtration.

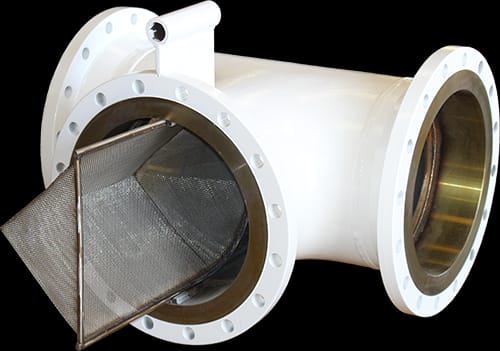

Tee strainers

Dynomech Tee strainers are a custom fabricated compound strainer designed to remove foreign particles from pipeline. T-type strainer is also known as Bathtub strainer. Tee Type Strainers are a low cost solution to large nominal bore straining requirements. They can be mounted into vertical or horizontal piping and can be configured for right-angled applications.

Dynomech T-Type strainers design is simplifies maintenance, because the stainless steel retainer wire holding the retainer in place is easily accessible through the blow down connection. Just remove the screen with a pair of pliers for easy cleaning or replacement. Tee type strainers are most typically equipped with a variety of graded filtration standards (fine to coarse or vise – versa) to ensure that the device performs at the appropriate level of cleanliness when fully loaded. Tee strainers include either a screwed cover or a quick-opening cover for easy accessibility.

Conical Strainers

Dynomech have a wide range of conical strainers. Conical Strainers are known as Temporary Strainers. The simple design of this type of strainer is commonly used in pipeline systems. The mesh cone shape offers a large filtration area, catching debris in pipes. This helps prevent damages to pumps, control valves, gauges, flow meters, and any other process equipment by catching materials before they damage the expensive equipment.

Conical Strainers are very cost effective straining solutions in many applications. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap. Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Conical Strainers are used in a wide variety of liquid straining applications to protect downstream process system components in many industries, including: chemical processing, petroleum, power generation and marine. Water handling applications, where conical Strainers are used to protect equipment that could be damaged or clogged by unwanted sand, gravel or other debris, are very common.

Y Type Strainers

Dynomech Y Type Strainers designed in fabrication as well as in casting. Y Type strainer remove foreign matter from pipe lines and provides protection for pumps, meters, valves, and other similar mechanical equipment, which is called as Strainer. "Y" Type Strainers are named after their shape and normally used for course filtration. But with large filtration area can be used with fine mesh also. The Strainer improves the clearance in the medium, and prolongs the life of valves; protect expensive pumps, meters and other equipments. It is suitable for water, Air, Gas, petroleum, steam and other fluids.

A Y-strainer can be installed in either a horizontal or vertical position (Downward flow) with the screen element pointing downward. This allows the strainer screen to collect material in the strainer at the lowest point of the screen.

Suction Diffusers

Dynomech Suction diffusers are flow-straightening devices that provide maximum flow efficiency at the suction inlet of the pump while at the same time reducing space and fitting requirements. They also eliminate the need for an equivalent length of ten pipe diameters of straight run on the suction side of the pump. It is an elbow (and in some cases a reducing elbow) with a built in strainer that aims to provide easy maintenance and trouble-free system performance.

Many different industries use suction diffusers. For example, the process industry, metals, and mining, power industry, water and waste, chemical industry, pulp and paper, oil and gas industries all use suction diffusers.Also, suction diffusers are installed on the inlet of a pump to help a smooth inlet flow. Additionally, they remove objects from damaging the pump. Moreover, suction diffusers provide ideal flow conditions for the pump. Thus suction diffusers reduce the amount of pipe used to achieve a steady flow.